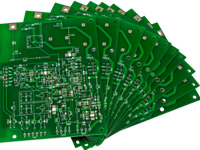

Double Sided

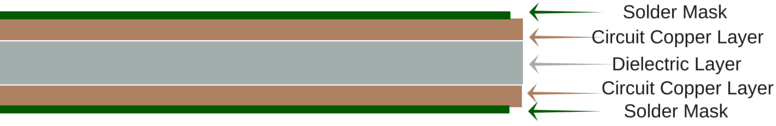

Double Sided PCBs (also known as Double-Sided Plated Thru) circuits are the gateway to higher technology applications. They allow for closer (and perhaps more) routing traces by alternating between a top and bottom layer using vias. Today, double sided printed circuit board technology is perhaps the most popular type of PCB in the industry.

How Are Double Sided PCBs Made?

Benefits of Double Sided PCBs:

- More flexibility for designers

- Increased circuit density

- Relatively lower costs

- Intermediate level of circuit complexity

- Reduced board size (which can reduce costs)

Applications of Double Sided PCBs

There are nearly limitless applications for old and new designs. Fine line surface mount, ultra high copper build, high and low temperature, Solder coated, Silver, and Gold finishes are just a few examples of DSPTH applications.

The following are applications in which Double Sided PCBs can be used:

- Industrial controls

- Power supplies

- Converters

- Control relays

- Instrumentation

- Regulators

- UPS systems

- Power conversion

- HVAC

- LED lighting

- Hard drives

- Printers

- Phone systems

- Power monitoring

- Automotive dashboards

- Line reactors

- Test equipment

- Amplifiers

- Traffic systems

- Vending machines