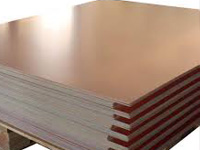

Metal Core

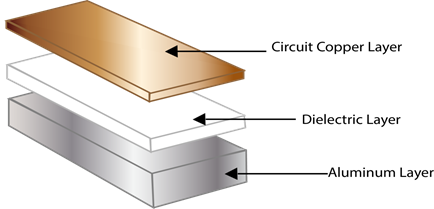

Aluminum Printed Circuit Boards Contain a Thin Layer of Thermally Conductive Dielectric Material that Transfers Heat

There are many names for these products; Aluminum clad, aluminum base, Metal clad printed Circuit Board (MCPCB), Insulated Metal Substrate(IMS or IMPCB), Thermally conductive PCBs, etc… but they all mean the same thing and perform the same way.

How Are Aluminum PCBs Made?

A thin layer of thermally conductive but electrically insulating dielectric is laminated between a metal base and a copper foil. The copper foil is etched into the desired circuit pattern and the metal base draws heat away from this circuit through the thin dielectric.

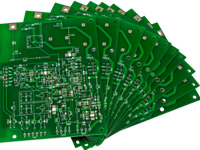

Benefits of Aluminum PCBs

- Heat dissipation is dramatically superior to standard FR-4 constructions.

- The dielectrics used are typically 5 to 10 times as thermally conductive as conventional epoxy-glass and a tenth of the thickness

- Thermal transfer exponentially more efficient than a conventional rigid PCB.

- Lower copper weights than suggested by the IPC heat-rise charts can be used.

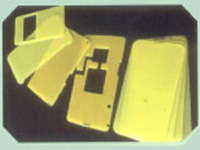

Applications of Aluminum PCBs

Although Power Converters and LEDs are the largest users of these products, Automotive and RF companies are also looking to take advantage of the benefits of these constructions. While a single layer construction is the simplest, other configuration options are also available on request.